- Home

- Electronics Plastic Injection Molding

WHAT IS ELECTRONICS?

Electronics refers to devices that operate using electrical circuits to control, process, or transfer energy and information. From smartphones and laptops to appliances and industrial machinery, electronics are essential to modern living. Their growing complexity and demand for durability have increased the need for advanced manufacturing techniques like plastic injection molding.

IMPORTANCE OF PLASTIC INJECTION MOLDING FOR ELECTRONICS

Plastic injection molding plays a pivotal role in producing high-quality electronic components. It offers numerous advantages:

Cost-effectiveness: Plastic is lightweight and affordable, making it ideal for high-volume production.

Safety: With superior electrical and heat insulation properties, plastic enhances the safety of electronic products.

Durability: Resistant to corrosion and wear, plastic ensures longevity in electronics.

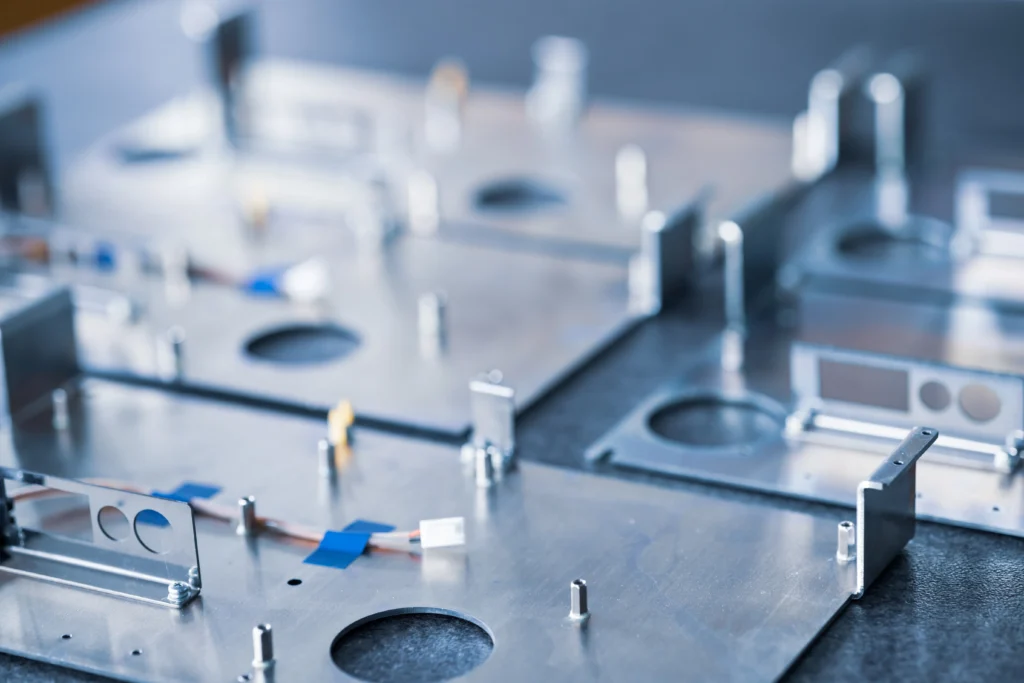

OUR PRODUCT PORTFOLIO FOR ELECTRONICS IN MALAYSIA

Pro-fine Plastics Sdn. Bhd. has demonstrated expertise in producing plastic injection-molded components for various electronic applications, including:

- Building Automation

- Telecommunication Devices

- Solar PV Systems

- Instruments and Gauges

- Consumer Electronics

- Security and Surveillance Systems

ELECTRONIC PLASTIC INJECTION MOLDING MANUFACTURER IN MALAYSIA

With over 28 years of industry expertise, Profine Plastic is a trusted name in plastic injection molding company for electronics. We are operating with certified qualifications such as ISO 9001:2015 and UL No. E198785 certifications to ensure our service remains top-notch standards at all times. Moreover, we also offer tailored custom plastic injection molding services to meet the unique needs of our clients in Malaysia. Not to mention, our advanced technology in leveraging the complex plastic injection molding process with precision and efficiency. Lastly, our team of experts are committed to deliver timely and reliable support to our clients at all times.

FAQs FOR ELECTRONIC PLASTIC INJECTION MOLDING

What types of plastics are used for electronic components in the process plastic injection molding?

Common materials used in electronics plastic injection molding include ABS, PC (Polycarbonate), and Nylon. These plastics are renowned for their insulating properties, durability, and ability to perform in high-stress environments, ensuring your electronic components are safe and reliable for everyday use.

How do you ensure components meet electronic safety standards?

Our commitment to excellence means every product undergoes rigorous quality testing to meet industry safety standards. With UL-certified materials and precision manufacturing, our injection molding electronics process guarantees components you can trust, delivering peace of mind to both manufacturers and end-users.

Can you produce intricate designs for small electronic components?

Yes, our advanced machinery and skilled workforce make it possible to create high-precision, intricate designs tailored to your unique needs. From miniature sensors to complex circuit connectors, our expertise in electronic injection molding ensures your designs are brought to life with the utmost accuracy.

What electronic applications are suitable for your injection molding services?

Our electronics plastic injection molding services cater to a wide range of applications, including casings, connectors, sensors, and enclosures. Whether it’s consumer electronics or telecommunication devices, our solutions are designed to meet the demands of modern technology, ensuring your products are both functional and durable.