- Home

- ABS Plastic Injection Molding

WHAT IS ABS?

ABS, or Acrylonitrile Butadiene Styrene, is a versatile thermoplastic polymer widely used in custom plastic injection molding applications. Known for its affordability and ease of machinability, ABS is a popular choice among plastic manufacturers due to its excellent balance of cost-effectiveness and performance.

IMPORTANCE OF ABS PLASTIC INJECTION MOLDING

ABS plastic is renowned for its strength, toughness, and versatility, making it a top choice in plastic injection molding.

The adaptability of ABS makes it the most widely used polymer in injection molding, offering benefits such as dimensional stability, impact resistance, and ease of machining. Its ability to be customized for specific requirements ensures that ABS continues to be an ideal material for manufacturing high-quality, durable products across various industries including:

Automotive Industry: ABS plastic is commonly used for lightweight automotive parts such as seat belt components, door limiters, pillar trims, and instrument panels.

Consumer Industry: ABS plastic is found in household appliances like food processors, vacuum cleaners, and refrigerator linings, providing durability and ease of molding.

Electrical Industry: ABS is commonly used for electrical enclosures, connectors, and components, offering excellent insulation and protection.

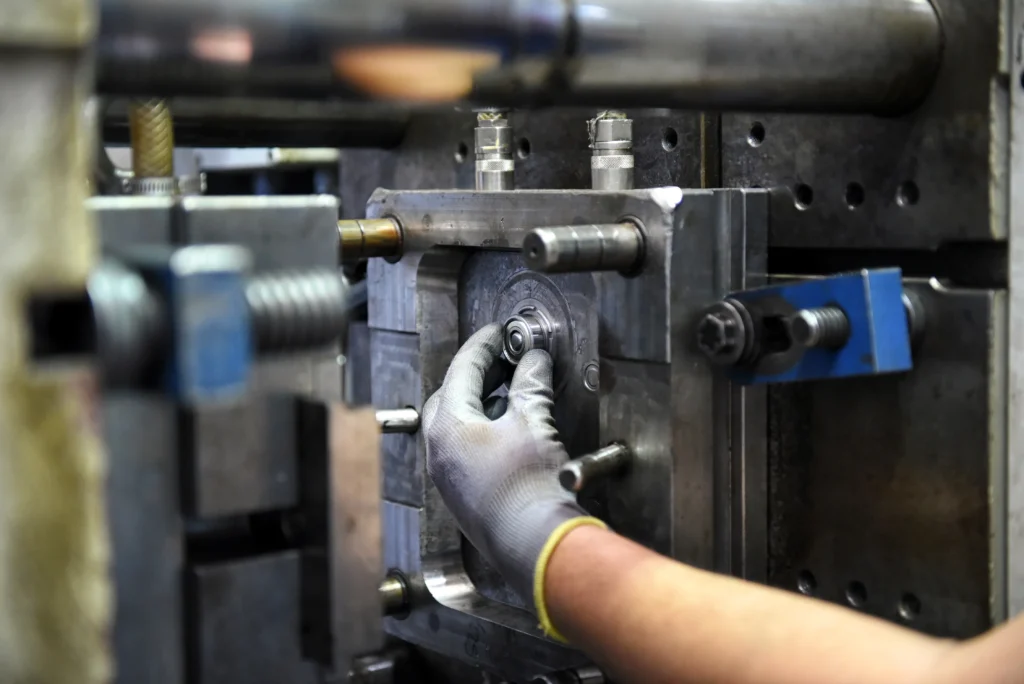

CUSTOM ABS PLASTIC INJECTION MOLDING MANUFACTURER IN MALAYSIA

At Pro-fine Plastics Sdn. Bhd., we stand out as a trusted partner for ABS plastic injection molding in Malaysia, offering cost-effective solutions without compromising on quality. With over 28 years of industry experience, we possess the expertise to deliver precision parts tailored to meet the unique needs of various industries.

Our commitment to excellence ensures that each product exceeds customer expectations. We are certified to ISO 9001:2015 for quality management and hold UL No. E198785 certification for plastic parts, assuring that our products meet the highest industry standards.

We pride ourselves on being responsive to our customers’ needs, providing prompt and effective solutions to any inquiries or requirements. Additionally, our customized plastic injection molding services allow us to create solutions that are perfectly suited to specific applications, further enhancing our value to clients.

When you choose Pro-fine Plastic, you’re partnering with a company dedicated to delivering high-quality, cost-effective, and tailored solutions that drive success for your business.

FAQs FOR ABS PLASTIC INJECTION MOLDING

What is ABS plastic, and why is it commonly used for injection molding?

ABS (Acrylonitrile Butadiene Styrene) is a durable, lightweight, and versatile thermoplastic, making it ideal for applications requiring impact resistance and high surface quality.

What industries commonly use ABS plastic injection molding?

Industries such as automotive, consumer electronics, and household appliances often use ABS plastic due to its strength and flexibility.

Can ABS parts be customized in terms of color and finish by an ABS plastic molding manufacturer?

Yes, ABS parts can be customized with various colors, textures, and finishes through techniques like spray painting and hot stamping.

What are the temperature tolerances for ABS plastic components suitable for injection molding ?

ABS performs well in temperatures ranging from -20°C to 80°C, making it suitable for both indoor and outdoor applications.